Sona’s Platform Technology:

Uniquely biocompatible

gold nanorods (GNRs)

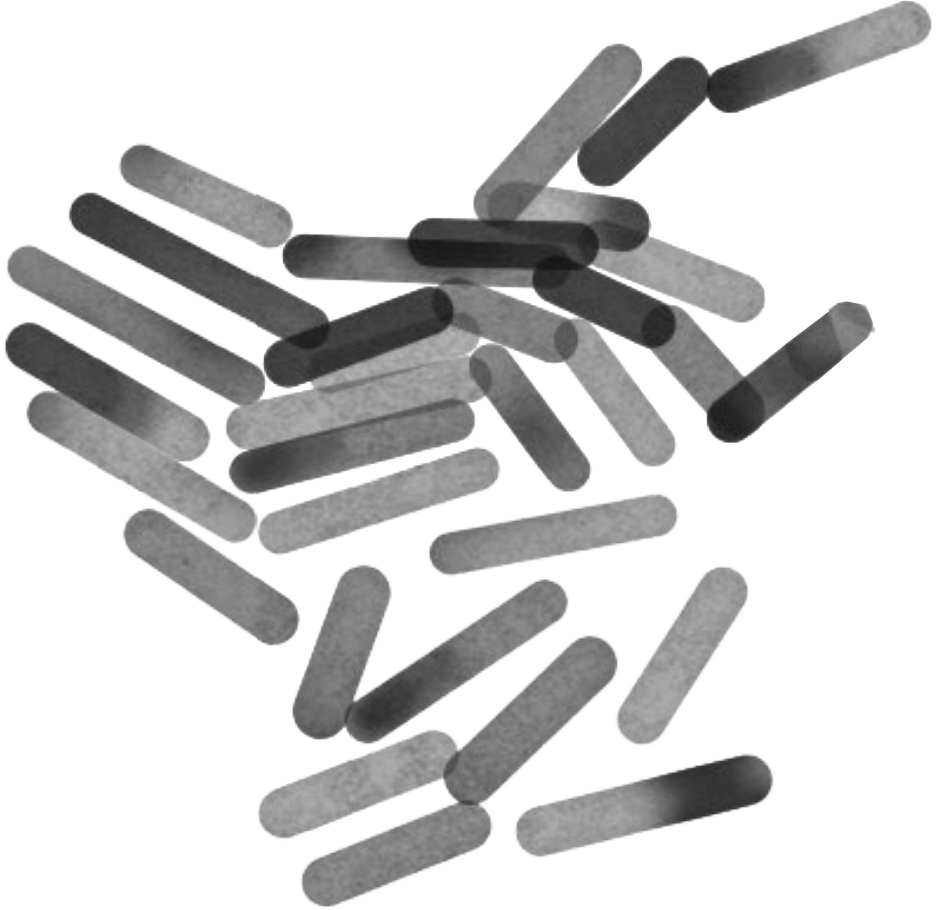

What are gold nanorods

- Rod-shaped nanoparticles made of gold

- Sizes of 10 to 100 nanometers in length

- Nanometer is one-billionth of a meter

- Produced by chemical synthesis

- Can be conjugated to different molecules

Uses of gold nanorods

Their surface chemistry and physical properties make gold nanorods ideally suited for a variety of applications. Sona GNRs, having the added benefit of being biocompatible, could potentially help to shape advancements across a number of key areas.

- Photothermal therapy

- Tumor targeting activity

- Anti-bacterial activity

- Drug delivery vehicle

- Diagnostic markers for imaging

- Immunoassay and biosensing

Limitations of other nanoparticles

&

Sona’s GNR technology solution

Toxicity

Other gold nanorod’s require CTAB (cyltrimethylammonium bromide) for their manufacture process. CTAB is a known toxin that can kill cells and is therefore less suitable for in-vivo therapies.

Uniquely Biocompatible

Sona surfactant uses no CTAB

- Can convert infrared light energy into heat in the same way as CTAB-based GNRs.

- Potentially more suitable for use in the body.

Shape

Nanospheres, nanostars or nanoshells have

- Limited surface area

- Limited stability

- Limited penetration depth into cells

Limited ability to tune for resonance

Shaped as rods

Nanorods by Sona have

- Variety of lengths and widths to increase surface area

- Long shelf life and stable surface properties

Complex light polarization and novel optical properties for use in diagnostic imaging:

- High color intensity can lead to enhanced sensitivity in lateral flow tests

Sona’s GNR Technology Assessment:

U.S. Nanotechnology Characterization Laboratory

Positive Results of Second Assessment of Sona’s GNR Technology from U.S. Nanotechnology Characterization Laboratory

No endotoxin or microbial contamination detected in Sona's GNRs

“Getting the approval of regulators to run clinical trials for targeted hyperthermia therapy (“THT”) will require a mountain of compelling data. These NLC assessments of the biocompatibility of our core, gold nanorod technology, coupled with the existing small animal study data for THT will provide us with a great base on which to build in the coming months. As with the NCL’s January assessment of three earlier batches of Sona’s gold nanorods, this new assessment did not detect any endotoxins or microbial contamination. The assessment also found “no significant differences between the two lots by DLS (dynamic light scattering) hydrodynamic size, zeta potential, or gold concentration”.

- David Regan, CEO

New NCL Assessment of Sona’s GNR Technology Highlights Process Improvement Success

A significant reduction in free surfactant levels in nanorod dispersions, with the average dropping from 230.7ug/mL in prior assessed batches to 34.6ug/mL in the batches following process changes.

Sona’s laboratory has undertaken a manufacturing enhancement program in preparation for the production of the gold nanorods necessary for our anticipated pre-clinical trials and studies. This program has resulted in improved yields and reduced surfactant levels with no loss in stability or biocompatibility, as evidenced by these additional excellent NCL assessment results which we were very pleased to receive”

- David Regan, CEO

Our advancements in gold nanotechnology have the potential to transform the diagnostic, scientific, and medical treatment markets.

Our gold nanorod products offer a highly functionalized and robust manufacturing process.

- Lengths from 25-60 nm

- Typical widths from 10-15 nm

- CTAB free & Bio-Compatible

- Wide colour spectrum

- Long shelf life

- Functionalized surface properties

Sona’s GNR in Lateral Flow Assays (LFA’s) as diagnostic tools.

Gold Nanorods

Gold nanorods (GNRs) are small particles whose surface plasmon resonance (SPR) frequencies can be altered by modifying their length and width, giving them properties useful in a host of applications, including diagnostics, optical biomedical imaging, and photothermal therapies, to name a few. One of the major barriers in the application of GNR-based materials, however, especially for in-vivo applications such as hyperthermal cancer treatment, is the presence of cetyltrimethylammonium bromide (CTAB), a cytotoxic, cationic surfactant used exclusively in the large scale synthesis of GNRs. CTAB attacks and kills cells in the body in 2 ways: by creating nanoscale holes within affected cell membranes and depriving cells of energy, ultimately killing the cell in both cases.

The concentration of CTAB that is most often used in the synthesis of gold nanorods is typically 100 times its critical concentration, meaning a significant amount of CTAB remains in the bulk of the solution after the GNRs are made. A number of methods have been used to “remove” or partially exchange the CTAB, however, these surface modified GNRs are often still contaminated with residual CTAB.

For GNRs to be safely and more readily integrated into in vivo applications, removal of CTAB is essential. This is where Sona’s patented technology comes in. Our revolutionary process of GNR synthesis completely eliminates CTAB from the equation all together!